Mono-Si Texturization Additive MQT-810 Series

It's suitable for Mono standard, Mono PERC and TOPCon.

Stable Performance, High Efficiency

- SunFonergy's Mono-Si texturization additive has stable cell performance throughout process lifetime, including high efficiency, stable reflectance, consistent etch weight, and uniform surface morphology.

Strong Cleaning Performance

- It has strong cleaning performance, especially for mixed wafer sources without SDR process as well as rework wafers. There is also no residue crystallization in the bath.

High Compatibility

- It is compatible with wafers with low SDR weight or no SDR process. Even with different tooling machines or wafer sources, SunFonergy's additive can be easily tuned for optimal efficiency.

Download

Mono-Si Texturization Additive.pdf

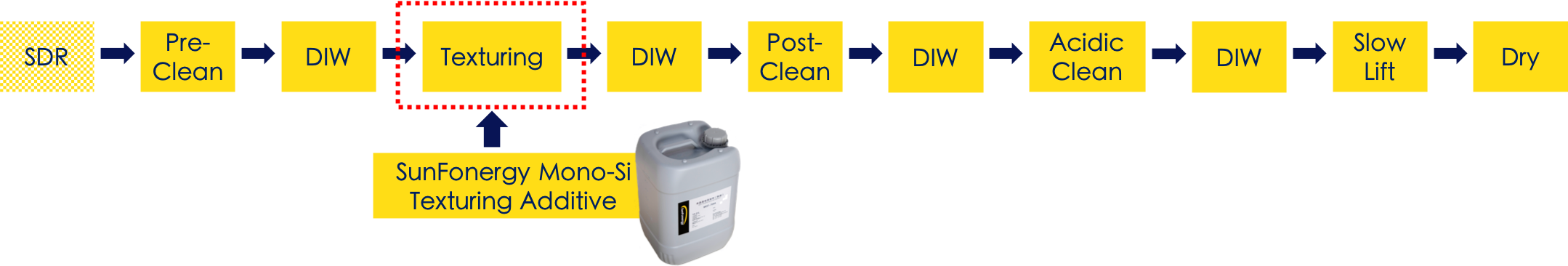

Process Flow

Mono-Si Texturing

Alkaline Polishing Additive BPL-719Series

Strong Cleaning Power

- SunFonergy's alkaline additive can more effecitively remove wafer residues, resulting in a cleaner alkaline polishing process.

Strong Protection, More Uniform Surface

- SunFonergy's additive can be used with both hot O3 (inline and batch type) and wet O3 processes. More uniform surface, smoother overlays among polishied pyramid bases.

Reduces Cost

- Reduces the post-cleaning bath's alkaline chemical concentration and/or removes the post-cleaning step.

Download

Alkaline Polishing Additive.pdf

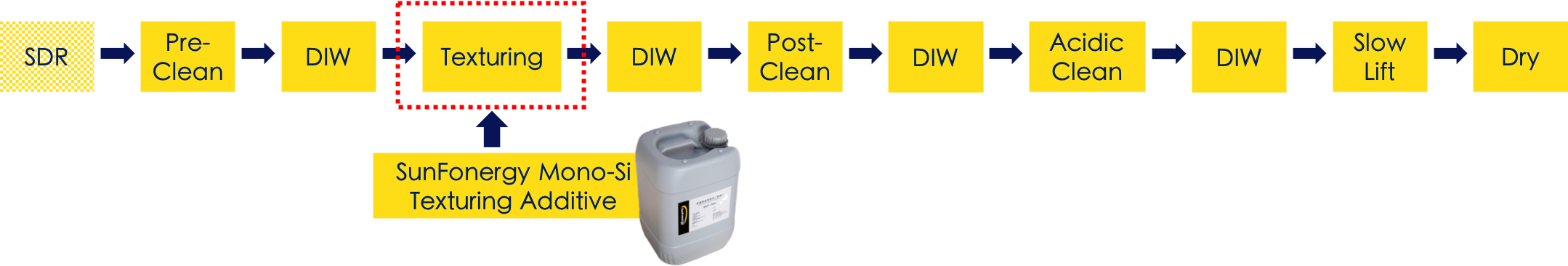

Process Flow

Mono-Si Etching

Mono-Si Texturization Additive MQT-809 Series

It's suitable for Mono standard, Mono PERC and TOPCon.

Stable Performance, High Efficiency- SunFonergy's Mono-Si texturization additive has stable cell performance throughout process lifetime, including high efficiency, stable reflectance, consistent etch weight, and uniform surface morphology.

Strong Cleaning Performance

- It has strong cleaning performance, especially for mixed wafer sources without SDR process as well as rework wafers. There is also no residue crystallization in the bath.

High Compatibility

- It is compatible with wafers with low SDR weight or no SDR process. Even with different tooling machines or wafer sources, SunFonergy's additive can be easily tuned for optimal efficiency.

Download

Mono-Si Texturization Additive.pdf

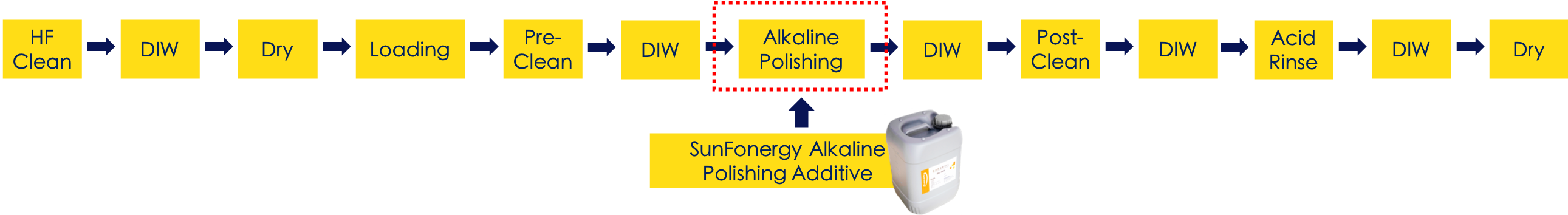

Process Flow

Mono-Si Texturing